THE VISITORS' faces lit up in wonder as the Blu-ray discs came off the 10-metre long production line. On being tested, the discs played perfectly the music video of Hong Kong artiste Danny Summer.

The visitors had gotten a first-hand experience of Anwell Technologies’ Blu-ray disc production equipment which the company had shipped to Frankfurt for the largest trade show in the world for the optical media industry.

The event: the MEDIA-TECH Expo 2008 from May 6 to May 8.

Anwell was the only exhibitor to operate a Blu-ray production line there.

It was impressive enough for Expedia Media, a California company which is into optical media manufacturing, packaging and distribution, to sign a deal on the spot to buy that production line for a seven-digit sum.

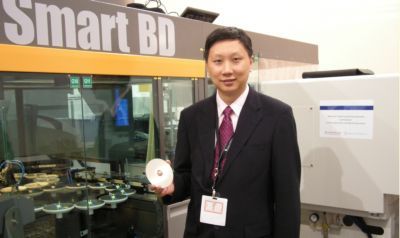

“After that, we were very happy to put up a SOLD sign with the name of Expedia Media on the machine,” recalled Ken Wu, executive director of Anwell, in an interview with NextInsight yesterday (Thursday, May 15).

Of the scores of visitors to Anwell’s booth, some could be potential customers in the future, said Ken.

Worldwide, Anwell – which is listed on the Singapore Exchange - is one of only two manufacturers of equipment that replicates Blu-ray discs. Sony of Japan makes the equipment too, but only for its own use.

Starting from Q4 of last year, Anwell has delivered Blu-ray disc replicating machines, and continued to receive orders after that. It takes between six and eight weeks to produce each machine.

The one that Anwell sold at the Frankfurt trade show was part of US$6.5 million worth of deals which Anwell clinched there. The other three orders were for equipment that replicates DVDR and DVD pre-recorded discs. Delivery will start in Q3 this year.

Two of the orders came from Laserdisc, the largest disc manufacturer in Argentina with plants also in Chile, Peru and Costa Rica. Anwell’s DVDR production line – SL2D - will be the first to be installed in Argentina.

Order book

Aside from the contracts clinched at the trade show, Anwell had HK$111 million of inventories in the form of finished and semi-finished manufacturing equipment as of Mar 31. The equipment will be shipped in the coming quarters and be recognised as sales in Anwell's financial statements.

This compares with the HK$57 million worth of equipment sales in Q1.

In its Q1 results announcement, Anwell said its equipment sales was sluggish as optical disc manufacturers had been facing a dilemma whether to expand on the existing DVD format or to make new investments on the Blu-ray disc format.

After Toshiba announced in February this year that it would not continue to invest in the competing HD-DVD format, the optical disc manufacturers had a clear picture that the future format would be Blu-ray.

The low equipment sales in Q1 contributed to the group’s net loss of HK$17 million, compared to a HK$203,000 gain in Q1 of last year.

“This business can be lumpy but in we are still in an industry upcycle driven by Blu-ray and by investments in DVDR format by manufacturers,” said Ken.

Anwell’s total turnover in Q1 was HK$226 million, of which HK$169 million were contributed by the media products manufacturing and trading business.

The media products manufacturing division suffered a 10% drop in production capacity as some equipment was used for R&D to enhance the efficiency of all the machines, said Ken.

The R&D project has now been completed. By the end of this quarter, as a result of the R&D, the total production capacity will reach 20% higher than in Q1, said Ken.

On the horizon is a new business that Anwell is taking flight towards. It is the solar energy business, which uses common technologies with optical disc business. These include thin-film technology, vacuum technology, and automation.

For its first customer, Anwell has signed a preliminary agreement with Brazil Energy for the sale of a turnkey production line for thin-film silicon solar modules.

Brazil Energy intends to purchase the Anwell Sunlite-120 line with an initial capacity of 40 MW (megawatts) per year. Anwell has not finalized the sale price but the market rate is about US$250 per watt, which suggests that Anwell’s machine could fetch US$100 million before discount, if any.

The equipment will be delivered in the second half of next year.

Separately, Anwell has also entered into a preliminary agreement with Brazil Energy for the sale of up to 5MW of thin film silicon solar modules. Delivery is expected to start in Q1 next year, which will enable Brazil Energy to get a head start in the solar energy business without having to wait for the manufacturing equipment to be ready.

For this solar cell business, Anwell is starting up a plant in Henan, China, as well as talking to other potential customers in the solar energy industry, said Ken. Worldwide, there are three other players in the manufacture of thin-film solar modules and their capital equipment.

Recent NextInsight stories:

ANWELL breaks into solar cell market as tipping point dawns

ANWELL: Returning to the black; potentially greater profits ahead